SANDWICH PANELS

SANDWICH PANELS

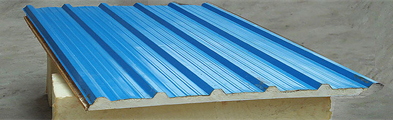

A sandwich panel is any structure made of three layers: a low-density core (PIR, mineral wool, XPS), and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required. Basically it is a product used to clad the walls and roofs of buildings. Each panel comprises a core of thermo insulating material, skinned on both sides with sheet metal. Sandwich panels are not structural materials but curtain materials. The structural forces are carried by the steel framework or other carrier frame to which the sandwich panels are attached.

MAIN FEATURE OF THE SANDWCH PANEL IS - Sandwich panels, protecting you against the external factors on all sides of your building, are produced by filling in a thick and low density insulation material between two thin and high density metal surfaces. These ready-assembled building elements, which have a high load carrying capacity despite their own low weight, are produced on continuous lines.

Different insulation materials should be chosen according to the needs of the buildings. Sandwich panel production is made in all insulation types including PUR, PIR, Mineral Wool and EPS. You can decide which type of sandwich panel is suitable for your building/project by taking into consideration the thermal, humidity, sound insulation and fire resistance needs of thereof.

Sandwich panels are generally used in industrial facilities, commercial buildings, cold storages, residential buildings, power plants as well as buildings for agricultural and husbandry.

THE LIFE OF SANDWICH PANEL

Sandwich panel, which is a composite material, is formed by filling insulation material between two metal surfaces.

The longevity of sandwich panels depends on designing to choose the right technical specification of product components according to the needs of the building, the environment and climate conditions in which it is located.

Outer sheet of the sandwich panel should be resistant to temperature changes, UV rays and external effects. The inner sheet should be resistant to chemical and physical effects as well as condensation, which may result from the inner atmosphere of the building.

Moreover, the load carrying capacities of sandwich panels, designed with the insulation material matching the needs of the building, must be calculated correctly based on the load they will carry.

SANDWICH PANEL LAYERS

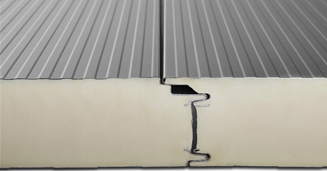

Ensuring thermal and acoustic insulation and waterproofing, as well as fire and load resistance for your buildings, sandwich panels are produced in 3 layers – inner sheet, outer sheet and insulation core.

Why use sandwich panels anyway?

- Fast and Easy Installation Contrary to the traditional systems, continuous line manufactured sandwich panels are in fully compatible and ready to assemble pieces that are prepared in the required dimensions, insulation types and colors based on the structure of your facility, with engineering and quality control processes conducted beforehand at the factory.

Installation of the sandwich panels is very easy with the few joints on wide surfaces. By means of advanced transport opportunities and mechanical lifting equipment, the duration of carrying and cladding is remarkably shortened. Therefore, your project is delivered in a short span of period, allowing you to save time. - Perfect Thermal Insulation Thermal insulation means reducing the energy spent in winter for warming and in summer for cooling; and taking measures to prevent heat transmission with the objective to live in comfortable environments. Sandwich panel is a building material, which is very suitable for thermal insulation.

Sandwich panel provides high thermal insulation by means of PUR, PIR, EPS and Mineral Wool insulation materials. Thermal insulation with sandwich panels prevents problems such as mold and humidity resulting from heat movements and condensation, and ensures your building to be robust and long-lasting. - Investment Economy In many types of buildings, you can save up on both building and installation time by selecting the appropriate sandwich panel. Thanks to its feature of easy mounting, you can conduct expansion and renovation works without interrupting everyday activities in the building. Moreover, the panels are both economic and practical as they can be disassembled and reused.

The lightness of sandwich panels allows you to gain advantage with regards to transport and main building costs. Also, their maintenance costs are low thanks to their durable structure.

In brief, sandwich panel is both a fast and aesthetic solution and budget-friendly for its longevity. - Aesthetic Appearance of Your Buildings The outlook of your building is just like the mirror of your dreams. That is why we add new ideas to our sandwich panels every day for the aesthetic of your buildings. You can enliven the outer walls of your building and obtain an aesthetic appearance with the sandwich panels designed in different colors and in a structure that enables them to be positioned horizontally, vertically or angular. Thanks to their feature to be used in the internal sections as well, you can create different designs with the sandwich panels.

- High Fire Resistance If you choose a sandwich panel fit for your building in terms of fire insulation, you will be able to slow down the spreading of fire within the building and its surroundings, and to ensure the safety of life and property in the building.

- Air and Water Tightness Thanks to their perfect joint detail, Teknopanel sandwich panels prevent air and water leakage. While they ensure the continuity of thermal insulation, heat is not lost at any point of your building. Therefore, you take the heating and cooling in your building under control and ensure energy efficiency. With a watertight structure, sandwich panels ensure active hydro-insulation against natural conditions such as snow and rain, and prevent humidity and mold. Your building becomes stronger and more durable.

- Noise-Free Buildings Sound insulation is a must in order to minimize the harmful effects of noise on humans, to leave out the unwanted sounds, and to reduce the sound spreading around from noisy areas.

HOW MUCH DO SANDWICH PANELS COST, AND WHERE ARE THEY THE CHEAPEST?

The cost of purchase depends on the overall product thickness and its thermoinsulating core material. A ‘budget option’ is the use of EPS-core sandwich panels; however, for better long-term performance and cost effectiveness, panels with superior thermal conductivity coefficient are a better choice - such as PIR-core sandwich panels.

SANDWICH PANELS ARE MOST POPULAR IN CONSTRUCTING:

- Warehouse buildings

- Logistic hubs

- Sports facilities

- Cold stores and freezers

- Shopping malls

- Manufacturing buildings

- Office buildings

Sandwich panels can be combined with other structural solutions. A popular option is to install the panels as external cladding for the outer walls of shopping malls, including sandwich-layered roofing structures: box profile sheets, thermal insulation (e.g. Thermano PIR-core sandwich panels), and a waterproof membrane.

PUF PANELS

PUF panels are sandwiched panels made of polyurethane which is usually sandwiched between two metal sheets. Sandwich puf panels are widely used in steel structures in the present day due to their various advantages. PUF panels are also available in different sizes depending on the requirement and a PUF panel supplier or PUF panel manufacturer should be able to design them according to your specifications.

A PUF panel’s core is made of polyurethane while the interior and exterior are made up of thin metal sheets. This gives them excellent heat and sound resistance and insulating properties. Due to these reasons, they are commonly used in the construction of various structures such as airports, exhibition halls, cold storages, auditoriums etc.

Benefits of Sandwich Puf Panel Sheets:

- Energy Savings Due to Low Thermal Conductivity: PUF panels are good heat insulators so they can protect the inner environment from ambient heat and sunlight and can keep the indoors cool. This means lesser energy will be used to keep the premises inside the structure cool which can save costs incurred in indoor cooling during hot weather

- Reduces the Effect Of Noise Pollution: Due to the sandwiched structure of the PUF panels, they act as good acoustic shields. So, they don’t let the noise pass through and can protect the inner environment from outside noise. This is very beneficial in structures that are located closer to busy roads, highways or construction sites where noise pollution is heavy.

- Weather Resistant: PUF panels are resistant to extreme weathers such as winds, rainfall or snow and can keep the indoors protected from environmental effects. They are also resistant to corrosion so this kind of structure requires less maintenance as it can withstand adverse climates. This makes them easy to use in structures built on any kind of geographical location.

- Lighter and Easier To Install: PUF insulated sheets are generally lighter compared to their size and so can be moved around easily. It also makes handling them on the site easier where they are supposed to be installed. So, the installation can be done with comparatively less manpower. This in turn brings down the combined construction cost of materials and labor which results in more savings.

EPS PANELS

EPS panels refer to expandable polystyrene panels that are manufactured using polystyrene beads that are expanded to more than 50 times their size through a chemical process that uses heat.

Once they’ve melded, they’re compressed between PPGI sheets into varying sizes of EPS blocks through different moulds. These are further cut and shaped for different industry requirements. They are also customizable and can be manufactured in different densities as per client requirements.

Advantages:

- EPS panels are a viable option owing to their sheer strength and durability and are best suited for walls as well as roofing.

- They are designed to be earthquake and weather resistant and are waterproof, soundproof and heat and fire resistant.

- They are lightweight and thus easy to transport and install.

- They are an economical solution that also minimizes wastage.

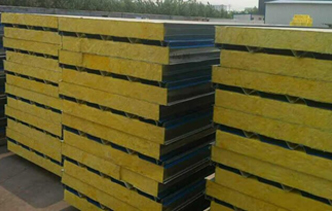

GLASS WOOL SANDWICH PANELS

These panels are insulating materials that are made up of glass fibers arranged using a binder into a texture similar to wool. Glass wool and stone wool are produced from mineral fibers. Mineral wool is a general fiber material that is formed by spinning molten minerals.

Glass Wool Panels are produced from the finest non-flammable glass fibers. These panels are cost-effective and durable. Besides this, Glass Wool Panels also serve excellent insulation properties and act as a barrier to the spread of fire.

Such Benefits of Glass Wool Panels are:

- Give proper soundproofing / Fireproofing walls, roofs, and ceilings

- Provide acoustic insulation chambers

- Using is partitioning

- Prefabric the shelters and accommodation

- Use in the health centers and pharmaceutical industry.